Tomorrow’s Vision, Operational Today

Bridging the gap between the digital twin and the physical world

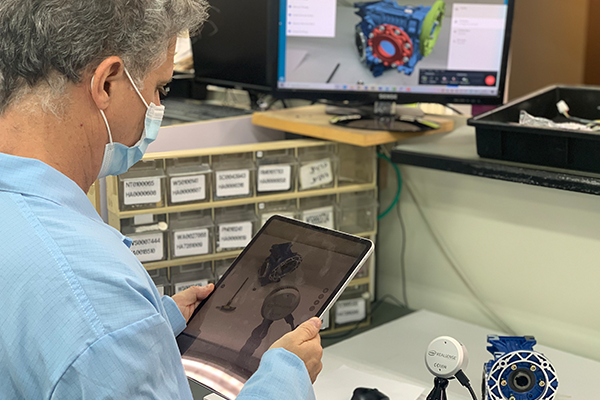

Simplify and save time by bringing real-time digital twins into the physical world

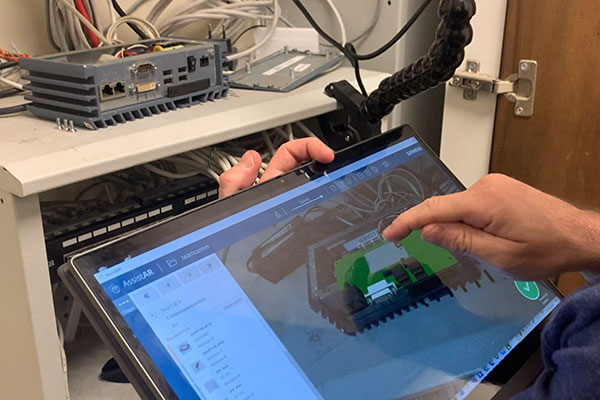

AN INNOVATIVE PATENTED APPROACH

Our patented technology leverages off-the-shelf depth cameras to bring the digital twin into the physical world.

High Reliability

Enhancing safety & usability

Precise & accurate

"Plug and play" with no need for data preparation

One Solution. Many Use Cases.

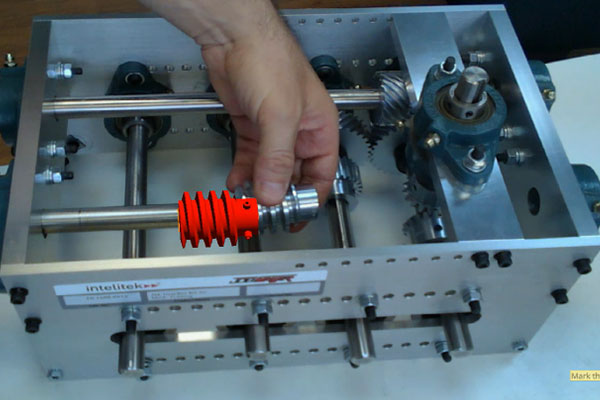

Live visual work instructions and 3D models for each assembly step, using AR and inspection technologies

Live work instructions

Increase quality and reduce the number of mistakes with automated validation, performed after each assembly step

Assembly-Validation

Reduce design iterations whilst saving time and prototypes costs with AR prototype

Virtual prototype

Inspect and analyze the weld points quality by measuring the distance between the nominal and actual positions

Weld point inspection

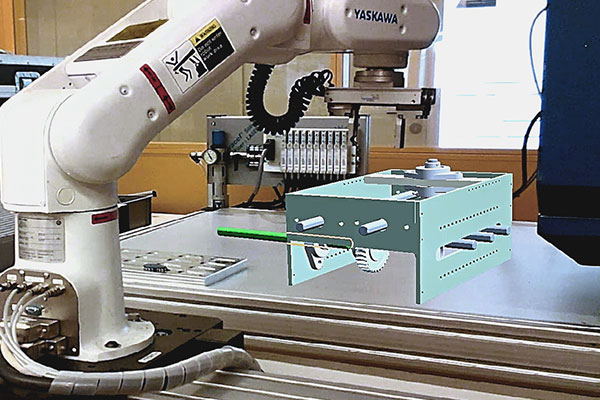

Ensure real-time alignment of digital and physical twins with faster commissioning times

“As Built vs as Designed”

Assesses if the system layouא corresponds to its design by comparing the physical system with the one designed

Manufacturing cell layout validation

Allow remote operation using AR-based remote monitoring & control tools

Remote assistance

Accelerate learning curves by guiding operators through the process, helping beginners get it right on the first time

Training

Proven Boost to Productivity

across Industries

SkillReal is realizing its mission to deliver accurate & reliable next-generation Digital Twin technologies across industries, helping global manufacturers to significantly improve productivity and quality.

Solution Partner

Jointly Bringing Best-in-Class Digital Twin Manufacturing Solutions to Siemens Customers Worldwide