SkillReal

Digital Twin Alignment

Greater efficiently at all stages – from design to production to market

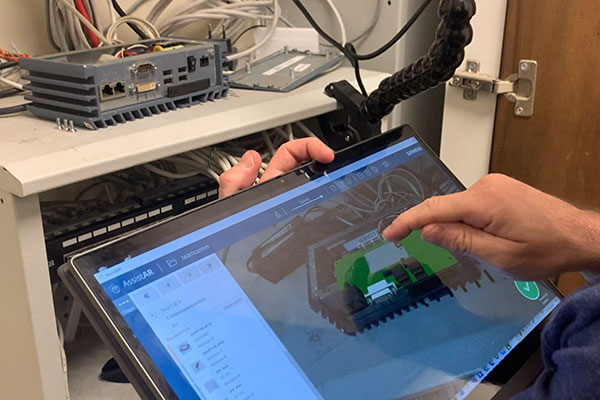

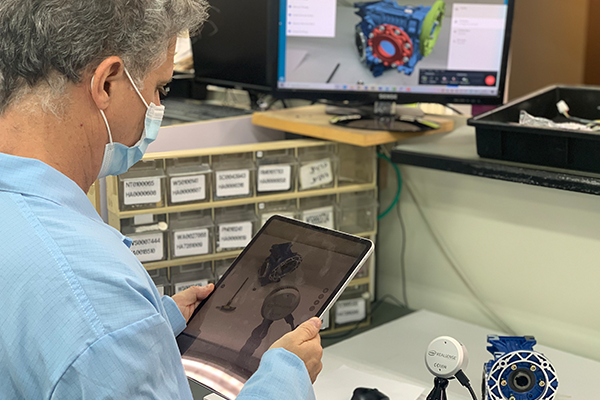

SkillReal Digital Alignment (DTA) allows for a shorter commissioning process when installing or upgrading a new production line by bringing the digital twin into the physical world. It enables early identification and correction of line setup and retrofit errors as well as accurate inspection of process points of manufactured parts.

SkillReal Digital Twin Alignment (DTA) shortens timelines, reduce costs, and minimizes the need for experts to be onsite by enabling them to work remotely.

SkillReal Digital Twin Alignment (DTA) provides the following capabilities:

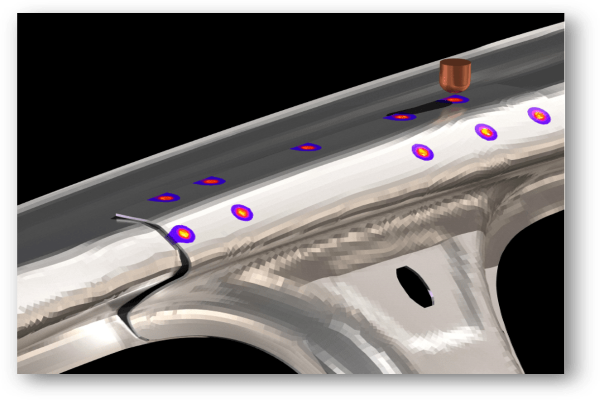

- AR visualization of the digital twin and the “heat map” of its deviation from the physical twin.

- Real-time 3D scanning of the manufacturing cell.

- Mark physical objects (such as fences) that might collide with virtual objects (like robot safety zones).

- Straightforward on-screen measurement and comparison of both the physical and virtual worlds

Supported Manufacturing Line Use Cases

Verify “As-built vs. As-designed”

Process Points Marking & Inspection

Virtual Prototypes & Robot Manual Touchup

Process points marking

Accurate measurements

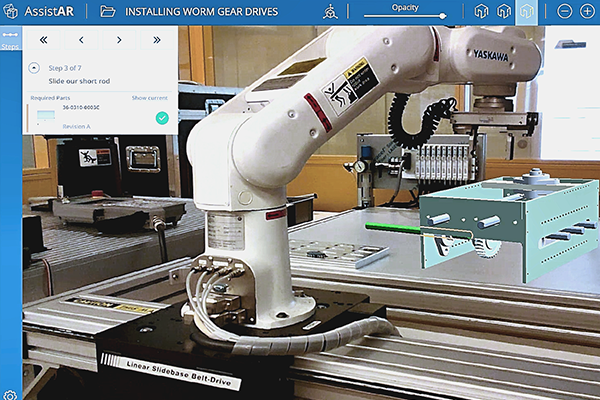

AR Work Instructions for Setup & Retrofit

Remote AR Support and Guidance

Training for Shorter Onboarding Process

Save Costs, Shorten timelines and Improve Quality

Time efficiency

- Shorter commissioning process

- More effective processes with virtual prototyping

- Inspection capabilities to identify errors and to reduce down time

Quality

- Remote expert interface for faults identification

- Ensure ‘built as designed’

- Early identification of line setup and retrofit errors

- Accurate inspection of process points of manufactured parts

Cost savings

- Early detection and error solving

- Save on prototype costs

- Lower traveling costs of experts who can now work remotely

- Shorter down time and reduced time to market

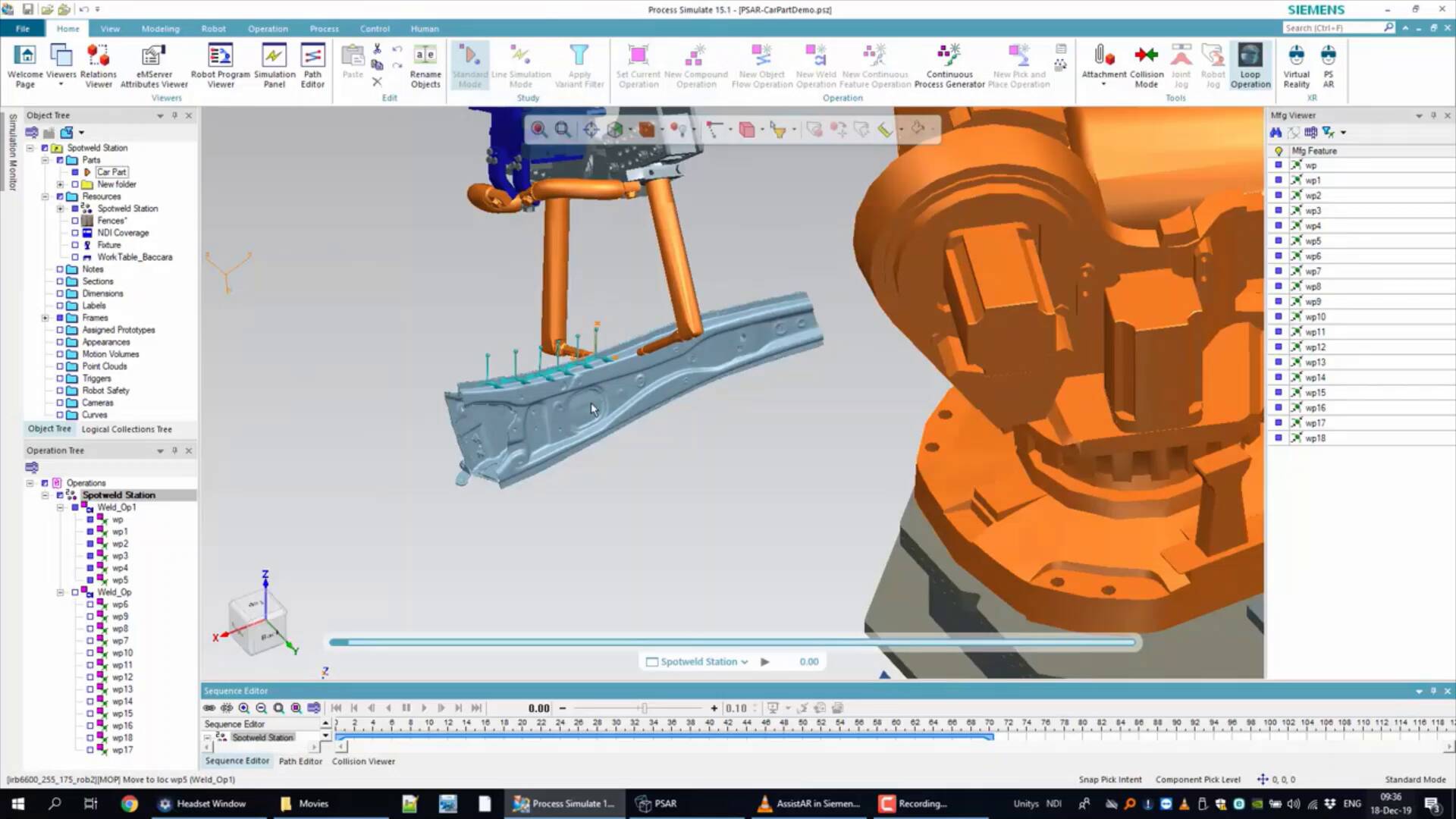

Seamless Integration

with PLM Systems

Plug-and-play integration with PLM/MES systems, automatically accessing and retrieving most updated work instructions and 3D models. This eliminates errors and costs derived from the preparation and updating of the work instructions.

Watch SkillReal Digital Alignment in action