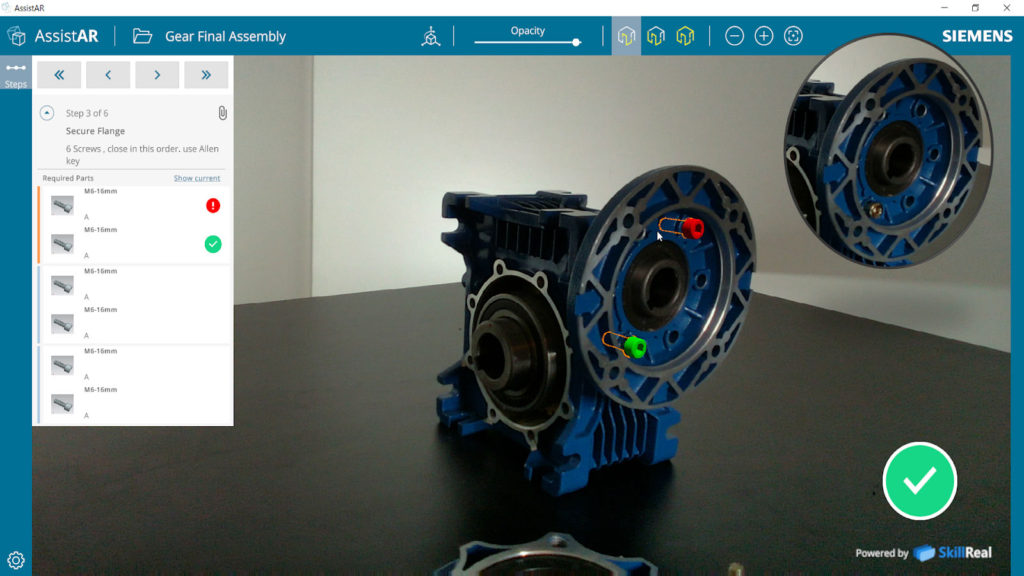

The increased complexity of products and manufacturing processes and the lack of skilled labor bring new challenges in the world of production. To answer these challenges SkillReal has developed AssistAR, a new generation of accurate Augmented Reality (AR) and inspection solutions for the manufacturing lines. AssistAR improves productivity, quality of assembly, maintenance, and installation activities. From table assemblies to large installations, the SkillReal system provides real-time work instructions, assembly validation, reports, and remote assistance.