Cut Dimensional Inspection Costs – Sub-mm Accuracy, within Cycle, No Robots

Greater efficiency at all stages – from prototype to pre-serial production

New camera calibration technology

Proprietary algorithms to calibrate cameras, even with wide-angle lenses, at a sub-pixel level, to transform the cameras into an accurate inspection tool.

Fast and Accurate 3D AI Detection

Patented accelerated Pre-trained large AI models enable detection with 99.7% accuracy of the required manufacturing features within the cycle time.

Accurate Dimensional measurements with Live Output

Up to 0.05 mm 3D precision for CAD-based inspection of large number of features with full integration to PLC, HMI and MES.

Supported Manufacturing Line Use Cases

Verify “As-built vs. As-designed”

Process Points Marking & Inspection

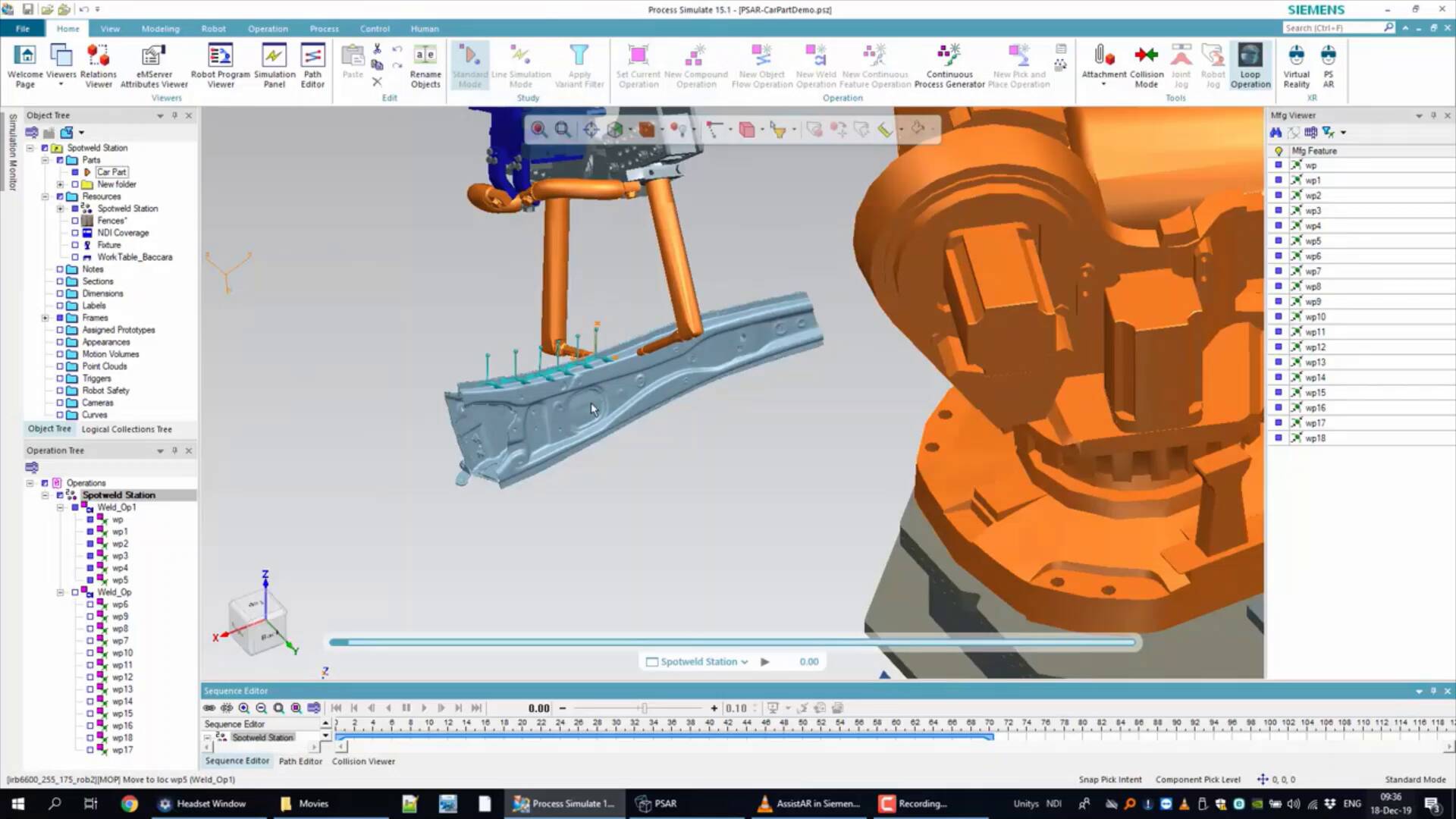

Virtual Prototypes & Robot PROGRAM CALIBRATION

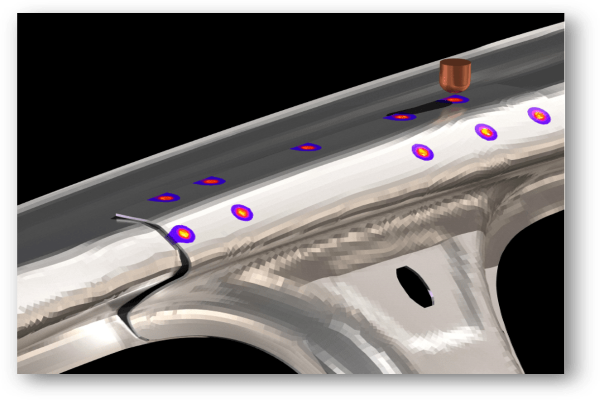

SUB-MM 3D measurements AND INSPECTION OF MANUFACTURED FEATURES LIKE WELD POINTS, STUDS

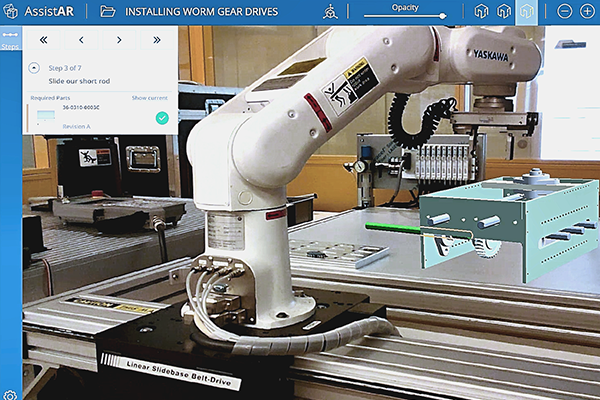

PROCESS POINTS INSPECTION, ALIGNMENT AND MARKING

Save Costs, Shorten timelines and Improve Quality

Time efficiency

No need for extensive AI training—SkillReal’s pre-trained large models deliver accuracy from day one.

Quality

Ensures every part and feature is inspected at cycle time—eliminating random sampling errors.

Cost savings

Minimizes manual inspection, reducing human errors, labor costs, and preventing expensive reworks and recalls.

Fully Compatible with Your Workflow

Seamlessly integrates into existing quality control systems, including PLC, MES, and PLM.

Watch SkillReal Digital Alignment in action