3D AI Platform for In-Line Inspection

Designed for Automotive Body-in-White

Patented algorithms with adaptive fusion of AI and image processing data, to enhance accuracy and reliability.

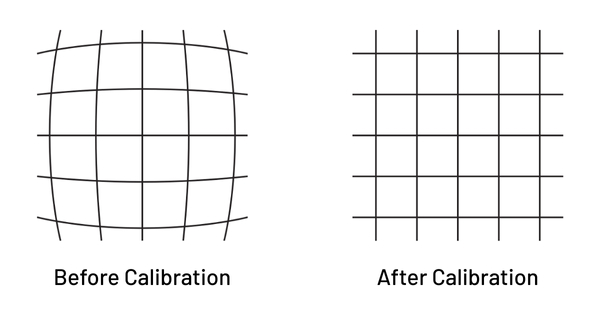

- New camera calibration technology – sub-pixel accuracy with standard cameras generate undistorted images in real time.

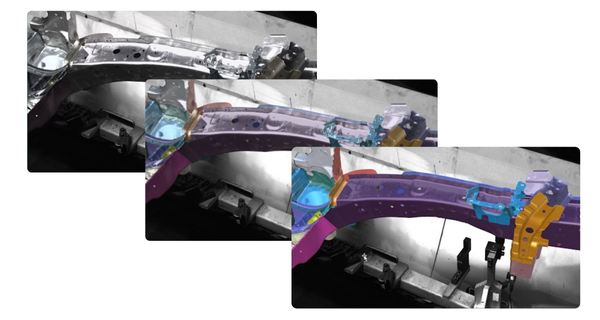

- Real-time sub mm Part tracking with CAD alignment – AI detections and 3D calculations are used to eliminate the need for dedicated Jigs or space.

- AI models– Patented accelerated Pre-trained large AI models, ready from day 1 with no need for part-specific AI training

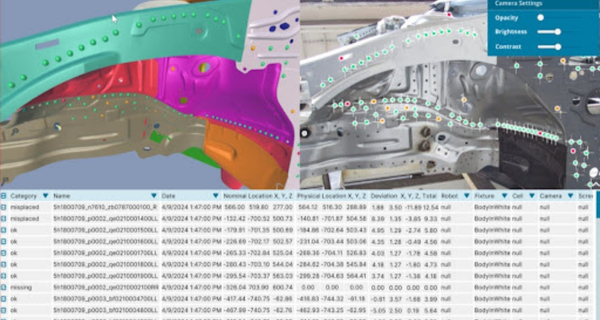

- Accurate Dimensional measurements and Quality inspection – all in one solution

- Pre-trained, high-performance Large AI models – Trained on over 35,000 real-world manufacturing variations and enriched with millions of augmentations

Plug-and-play with PLM Systems

EASILY DEPLOYED AND MAINTAINED

USING STANDARD PRODUCTION FLOOR EQUIPMENT – PCS AND STANDARD CAMERAS

SkillReal Technology

01

Camera calibration

Proprietary computer vision algorithms transforms standard cameras into high-precision 3D sensors by correcting lens and sensor distortions in real time, with sub-pixel accuracy across the entire field of view

02

CAD Based Alignment

AI-powered detection and proprietary 3D algorithms track parts with high precision, aligning each part to its CAD model for accurate 3D measurement and verification according to GD&T—inline, without jigs or complex fixturing

03

Accelerated Large

Pre-trained 3D

Dimensional AI models

Patented algorithm accelerates large pre-trained AI models by fusing them with geometric 3D data, enabling in-cycle inspection of 100% of features with high accuracy. Verifies presence, location and quality, with >99.7% reliability

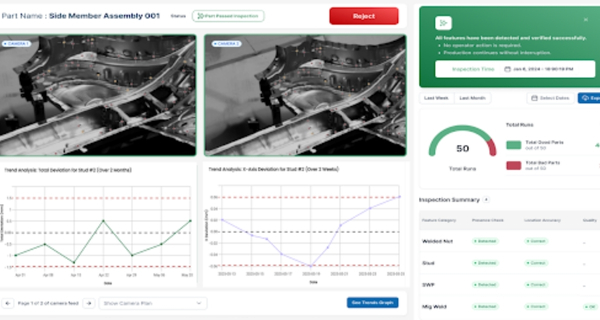

04

Open Platform and Advanced Analytics

Advanced analytics , AI and custom dashboards provide role-specific insights, and full digital traceability. Integrates with PLC, HMI and other factory systems to deliver real-time data for immediate corrective actions and quality improvement.